Project

Zinc Resources has constructed a $100 million zinc recycling facility in Victoria, Texas. The project will create more than 60 permanent jobs with a total payroll over $4 million - Approximately 45 of those jobs will be available to entry-level employees or skilled tradespeople.

Investments in Port of Victoria infrastructure will benefit the residents of this community for many years, spurring growth and job creation.

Zinc Resources is the inaugural customer of the The Port’s rail loop within the industrial park, generating an immediate return on investment to the Port.

The project is also a customer of a planned 50-megawatt substation that will bring additional power to the industrial park, leaving significant capacity for future development.

Zinc Resources has sponsored the installation of an oversized natural gas supply line that will provide additional capacity for future development.

Our Commitment.

Zinc Resources is committed to the health and safety of its employees and community and protecting our environment. These are a few of the ways we are going above and beyond:

Implementation and installation of new technology to achieve the lowest emissions in the industry

Installation of 25 voluntary emissions monitors

Utilization of a rubber lined floor/foundation to increase the resistance to dust emissions

Continual recycling of all process water - Even shower water is reutilized resulting in no process wastewater

Recycling filter bags and cartridges to recover trapped zinc and eliminate process solid waste

Installation of new technology to increase the efficiency and consistency of operations

Zinc Recycling.

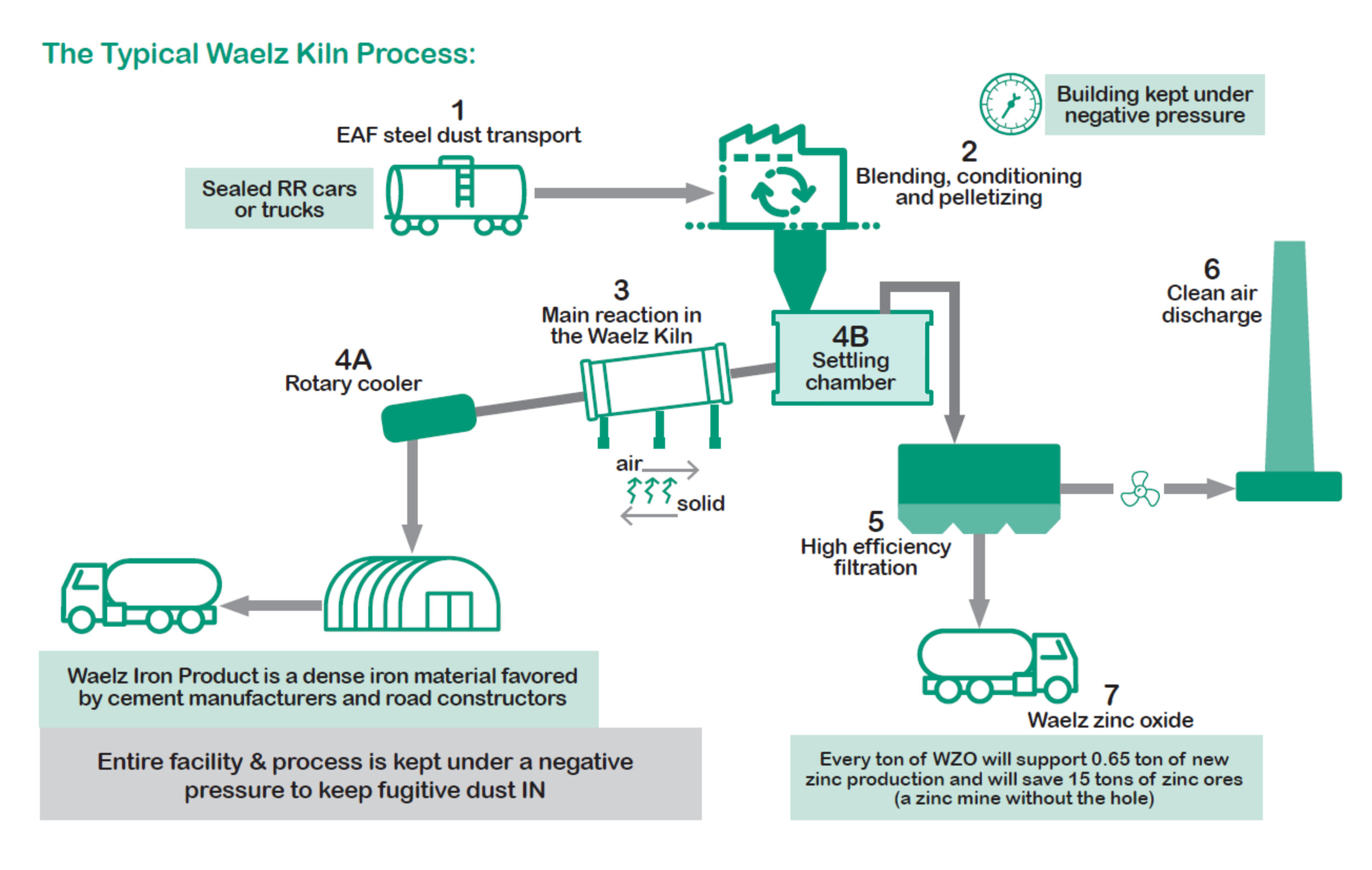

Zinc Resources utilizes the Waelz kiln process to extract zinc and iron from Electric Arc Furnace (EAF) steel production waste. This recycling service reduces the environmental impact of steel production by creating usable products from waste materials.

The environmental benefits of recycling:

Reduces the dependency on mined ores

Reduces steel wastes disposed in landfills

Reduces energy required to produce metals

Lower emissions than alternative or other processes

Zinc Resources reduces the environmental impact of steel production by converting steel production waste dust into useable zinc and iron products.

During the EAF process, a furnace melts scrap steel and produces dusts that are collected.

Zinc recycling facilities separate the zinc and iron in the dust.

Using the Waelz kiln technology, the recycling process allows two important natural resources - zinc and iron – to be reused.

Zinc Resources would sell WZO to zinc smelters, which produce pure zinc that can be used by the steel industry or other end-users for tires, medicines, sunscreens, vitamins, etc.

The second product, Waelz Iron Product (WIP) is used as a cement additive and in road construction.

The U.S. Environmental Protection Agency strongly supports safe and effective recycling and considers the Waelz kiln to be the most efficient method of recycling zinc from EAF dust. Zinc Resources is committed to recycling EAF dust safely and reliably while reducing waste, the environmental impact, and consumer costs associated with important everyday products.